As we’ve outlined in earlier blog posts, “kanban” is an organizational system that is tied to lean management practices.

If you’ve spent any time learning about lean management practices, you may have heard this term bandied about. The kanban board system is an integral concept tied to the just-in-time (JIT) production process identified by Taichii Ohno in the 1940s to improve Toyota Motor Corporation’s manufacturing system but there is a difference between kanban and jit.

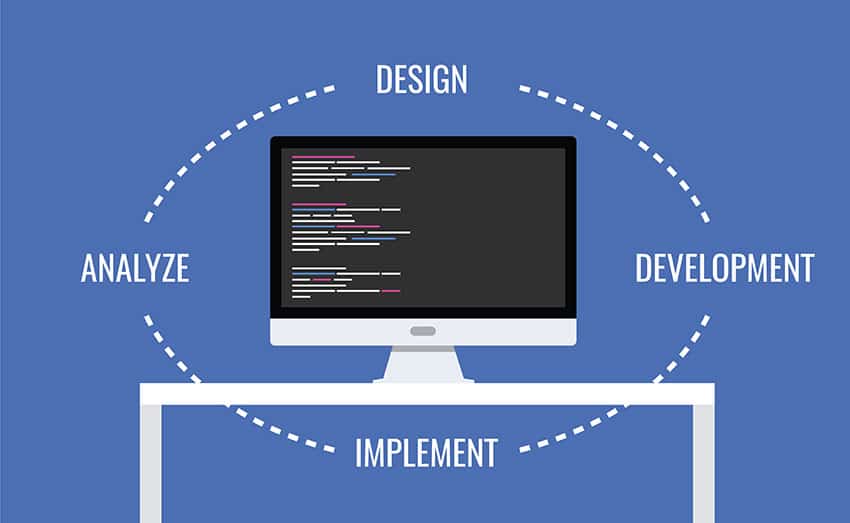

The word “kanban” is Japanese for “visual card” — a simple but apt description for the kanban board system. It’s a solution that allows team members to visualize the workflow for a particular project all in one place, including everything that needs to get done and all the tasks coming down the pipeline.

In its most basic form, a kanban is often created on a big whiteboard, with three columns and sticky notes in each column signifying various tasks. And modern kanban solutions, such as online kanban boards and kanban software, can alleviate the workload for over-stressed project managers while creating a sleek, collaborative workflow for team members.

And because these board systems are expandable to encompass tasks and projects for a single department or an entire multinational organization, this is an efficiency solution that works for a variety of industries. But who should be particularly interested? A variety of different companies are already making use of this solution, including organizations belonging to the following industries:

Manufacturing

Use of the kanban system in manufacturing is a given, considering lean management practices were originally devised to streamline operations on the Toyota manufacturing floor back in the mids 20th century.

But in the modern manufacturing environment, the transparency offered by the chanson system is ideal for streamlining the activities from the CEO all the way to the production line worker.

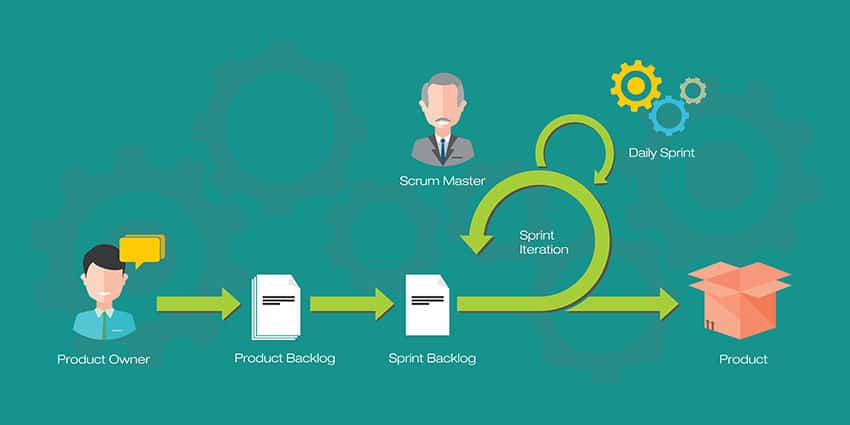

IT Departments

With a variety of tasks and projects on the go all at once, kanban solutions (particularly digital systems) are optimal for IT departments.

Whether there’s a help desk with innumerable technical tickets to sort through, or management of many servers, a kanban solution can help keep track, break up bottlenecks and delegate tasks more efficiently.

Service Industries

Kanban isn’t just a solution for companies that create physical products — it’s also ideal for service organizations. Luckily, manufacturers don’t own the patent on efficiency. While lean was initially thought up to help manufacturers become more efficient, these principles can also make sense for service industries. Changing the context doesn’t necessarily change the goals of lean: visualize, standardize and improve.

Health Care

In the fast-paced world of health care, organization and streamlined systems are essential. And many health-care organizations are already making use of a kanban-like system dubbed huddle boards. These are a tool that create more visibility for the day’s tasks and allows team members to raise and address issues.