Lean leaders spend an exorbitant amount of time focused on decreasing waste and increasing throughput.

Why? What’s the ultimate goal here? While the primary goal is to amp up customer value and streamline the production cycle as much as possible, what is this objective driving toward? The answer is a better bottom line. And that goal is where the Theory of Constraints comes in.

This theory focuses on managing constraints, or bottlenecks in the production process, all in an effort to boost a company’s profits. The Lean Enterprise Institute says TOC “conceptually models [businesses] as a chain, and advocates the familiar adage that a ‘chain is only as strong as its weakest link.’” And this theory examines and managers those weak links via a simple three-step process to streamline workflows and shore up any sluggish portions of the production process.

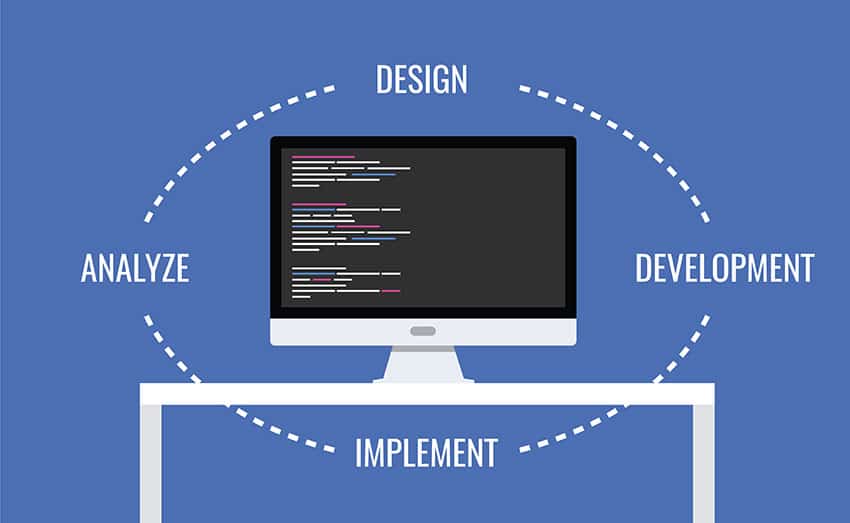

Step 1: Identify Constraints

Obviously, the first step is to take a hard look at the workflow or system and find those bottlenecks in the system. Where is the weakest link? What’s holding the workflow, system or organization back?

Keep in mind this could be a step in production, an entire process or something less tangible such as a policy or ineffective communication.

Step 2: Manage Constraints

Once you’ve identified the bottlenecks holding you back, the next step is to figure out how to cure this ill. The solution will obviously vary based on the constraint, your goals and your team, but these bottlenecks can generally be effectively managed.

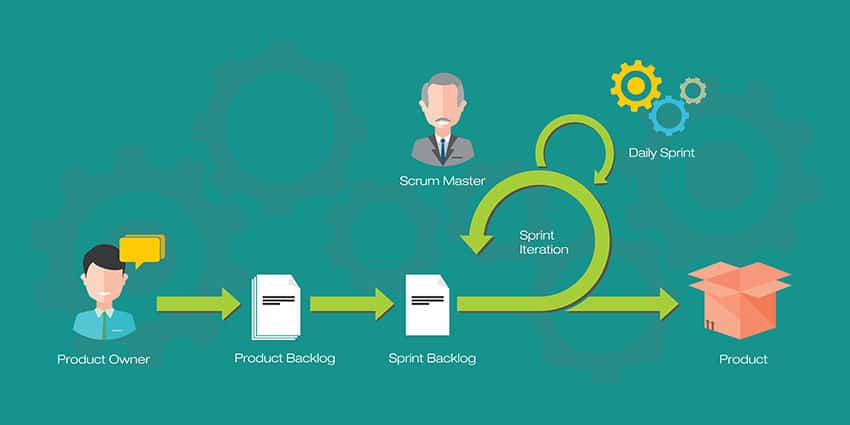

For example, a constraint could be a massive backlog of work on the design team. Perhaps reorganizing the team, delegating more work to other team members or re-examining the workflow process itself could help clear out that backlog and create a more efficient flow.

Step 3: Revisit and Evaluate

Once you’ve put your solution in place to manage that constraint, your job isn’t quite over. Now is the time to evaluate that quality of the fixes you’e implemented to cure that bottleneck.

Compare the process post-fix to key performance indicators prior to applying the theory of constraints steps. Are the fixes you constructed working? Is there something still holding back the workflow, system or team from achieving maximum efficiency? If so, it’s time to jump back to step two in the process, then lather, rinse and repeat as necessary.

The Bottom Line

While the Theory of Constraints is a relatively simple concept, it’s an effective tool to apply even in complex systems to boost a workflow’s overall performance.

It’s good for readers to know that, while the theory maintains that every system has a constraint, sometimes putting the appropriate solution in place to correct it may not be worth the minimal boost in efficiency. It’s really a matter of using your best judgement as a manager to deem whether the performance boost is worth the time and effort to eliminate the constraint.